Posted By: ITA-Admin | Date: May 14th, 2014

The electronics industry is currently witnessing a growth in component counterfeiting in which the supplier of parts to the assembler is often unaware. The complexity of the supply chain and the ingenuity of the counterfeiter mean it can be extremely difficult to detect that electronic components are counterfeit. Consequently, ITA Labs is offering a counterfeit detection testing service aiming to verify electronic components.

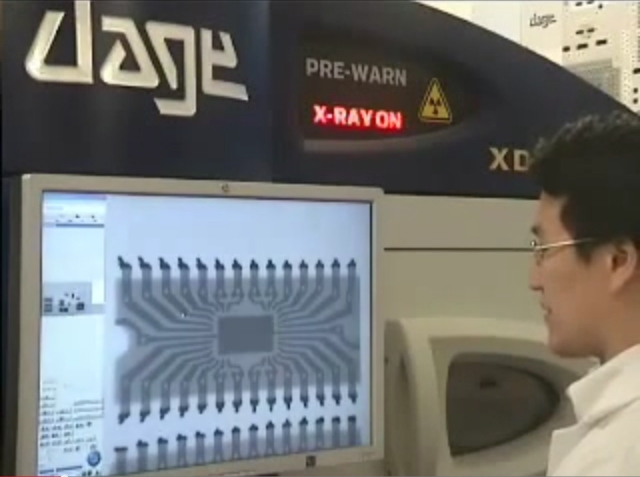

The counterfeit detection test service is based upon the latest generation of real-time X-ray examination equipment. The Dage XiDAT 7600 NT is used and it can detect discrepancies in bond wire configurations and lead frame patterns, as well as identifying the presence of a chip die.

This testing can be supplemented by wet chemistry techniques and optical microscopy in which the component housing material is removed and the chip die is exposed. This service offers the additional use of material detection techniques such as XRF (X-ray Fluorescence) and EDX (Energy Dispersive X-ray). These tests check the terminations of the package for finish compliance, such as lead in a lead-free coating.

“ITRI Innovation has invested considerable amounts of money in equipping the laboratory with counterfeit detection test equipment. With a team of high calibre electronics experts, we are in an ideal situation to solve any counterfeit project at one facility and through one single point of contact;” comments Dr. Wayne Lam, Laboratory Manager, ITA Labs. “At ITA Labs, we can offer the most cost-effective approach and depending on your needs, we can offer non-destructive testing methods.”