In aerospace, space and other performance critical sectors you need to be sure that the plating applied to pins, connectors and other components is within specification.

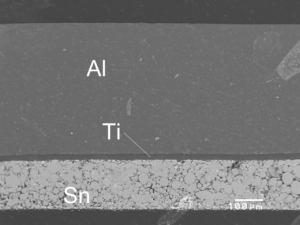

There are destructive and non-destructive ways of carrying out coating & plating thickness testing and checking for uniformity. The non-destructive method (using X-Ray Fluorescence) can be sufficient in some circumstances. The destructive method (using microsectioning and electron microscopy) is more thorough and enables presentation of results in a more usable format.

There are destructive and non-destructive ways of carrying out coating & plating thickness testing and checking for uniformity. The non-destructive method (using X-Ray Fluorescence) can be sufficient in some circumstances. The destructive method (using microsectioning and electron microscopy) is more thorough and enables presentation of results in a more usable format.

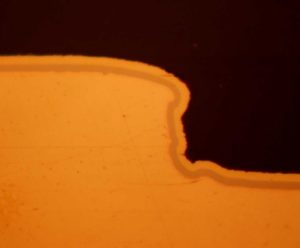

The challenge is to be able to carry out the microsectioning in a way that is repeatable in order to generate consistently reliable coating and plating thickness or uniformity results.

This is a task we carry out for a wide variety of clients. ITA Labs can do conformance or non-conformance testing and we can also provide ‘blind’ reporting, enabling you to make the judgement on suitability for purpose.

ITA Labs can also determine, through electron microscopy, the actual materials used in the coating or plating. This is often overlooked and all is not always as it looks.

In addition to XRF measurements and cross-sectioning, it is also possible to electrolytically determine metal coating weight or expose the coated part to chemical attack and measure the mass loss (e.g., to BS EN13046)

In addition to XRF measurements and cross-sectioning, it is also possible to electrolytically determine metal coating weight or expose the coated part to chemical attack and measure the mass loss (e.g., to BS EN13046)

We encourage our customers to have access to the laboratory and to work closely with us in any coatings or plating study or investigation. On completion of the work we issue a comprehensive and confidential report.

Our team of UK electronics experts is supported by a well-equipped chemical and metallurgical analysis laboratory. This allows coating & plating thickness testing or uniformity projects to be completed at one facility through a single point of contact.

We would be delighted to show you around our UK lab facilities and in particular, how we carry out the coating or plating thickness and uniformity testing.

To discuss your potential requirements, contact Tony at tony.wallace@internationaltin.org

+44 (0)1727 871328